With the rapid development of high technology, electronic products that are closely related to the public are constantly being updated, and the public also needs electronic products with high performance, small size and multiple functions, which puts forward new requirements for circuit boards.

The double-sided circuit board was born because of this. Due to the wide application of double-sided circuit boards, the manufacturing of printed circuit boards is also developing towards light, thin, short and small.

Double-sided circuit board characteristics

The difference between a single-sided circuit board and a double-sided circuit board is the number of copper layers. AiXun Precision Electronics Soldering Popularization:

Double-sided circuit boards have copper on both sides of the circuit board, which can be connected through via holes.There is only one layer of copper on one side, which can only be used for simple wiring, and the holes made can only be used for plug-in and cannot be connected.

The technical requirement of the double-sided circuit board is that the wiring density becomes larger, the hole diameter is smaller, and the metallization hole diameter is also getting smaller and smaller. The quality of the metallized holes on which the interconnection between layers depends is directly related to the reliability of printed boards.

As the pore size shrinks, the debris that has no effect on the larger pore size, such as brush debris and volcanic ash, will make electroless copper and electroplated copper useless once they remain in the small hole, and holes will appear without copper and become holes. Metallic deadly killer.

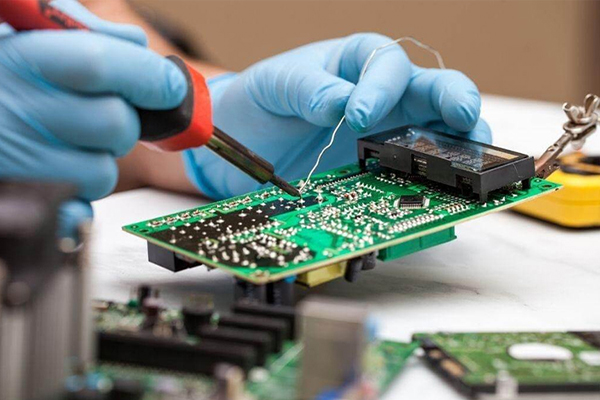

Soldering method of double-sided circuit board

In order to ensure the reliable conduction effect of the double-sided circuit, AiXun Precision Electronics Soldering recommends that the connection holes on the double-sided board (that is, the through-hole part of the metallization process) should be welded first with wires and the like, and the connection wires should be cut off. Pointed protruding part, so as not to stab the operator's hand, this is the connection preparation of the board.

Double-sided circuit board soldering essentials:

1. The devices that require shaping should be processed according to the requirements of the process drawings; that is, shaping first and then inserting.

2. After shaping, the model side of the diode should face up, and the length of the two pins should not be inconsistent.

3. When inserting devices with polarity requirements, pay attention that the polarity must not be reversed. Roller integrated block components, after insertion, no matter whether it is a vertical or horizontal device, there must be no obvious inclination.

4. The power of the electric soldering iron used for soldering is between 25 and 40W. The temperature of the electric soldering iron head should be controlled at about 242°C. If the temperature is too high, the head will easily "die". If the temperature is low, the solder cannot be melted. Soldering time is controlled within 3~4 seconds..

5. In the formal soldering, generally follow the soldering principle of the device from short to high and from the inside to the outside. The soldering time should be mastered. If the time is too long, it will burn the device and the copper clad line on the copper clad board.

6. Because it is double-sided soldering, a process frame for placing the circuit board should also be made to prevent the devices below from being skewed.

7. After the soldering of the circuit board is completed, a comprehensive inspection should be carried out to find out where there are missing plugs and missing soldering. After confirmation, trim the redundant device pins on the circuit board, and then flow into the next process.

8. In the specific operation, the relevant process standards should be strictly followed to ensure the soldering quality of the product.

The above is the relevant knowledge about double-sided circuit boards shared by AiXun. AiXun offer precision soldering stations, soldering iron, DC power supply etc. If you have any questions, welcome to contact us.

WhatsApp

WhatsApp