With the continuous innovation of network technology, various electronic products have also exploded, and the maintenance and assembly of electronic products have also become a part of people's lives. Soldering and desoldering are both indispensable for the maintenance of electronic product circuits. First, before soldering, we must be familiar with circuit components and master the skills of soldering and desoldering.

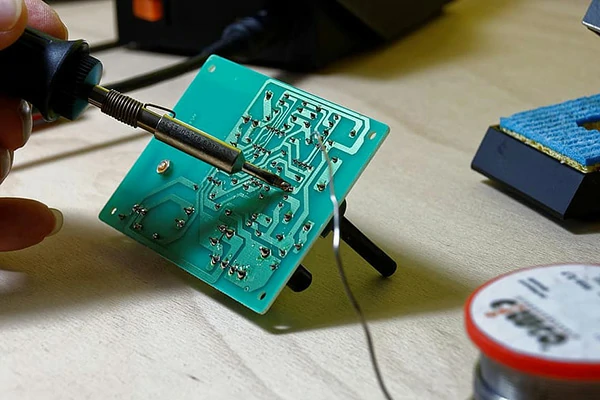

Soldering is a joining process used to join different types of metals together by melting solder. Solder is a metal alloy, usually made of tin and lead, which is melted by using a hot iron. Manual soldering is the basis of soldering technology and a basic operation skill in the assembly of electronic products. The operator holds the solder wire in the left hand and the soldering iron in the right hand, and enters the ready-to-solder state. When the solder on the solder joint fully wets the soldered part, the solder wire should be withdrawn in time to ensure that the solder joint does not have tin piling phenomenon and obtain a better solder joint.

The solder wire we generally use is 1.2-1.5 mm. When soldering, we hold the soldering wire in the left hand and the soldering iron in the right hand. When the soldering iron is close to the solder joint, we put the solder wire on the tip of the soldering iron. The amount of solder wire should not be too much. Too much solder wire will easily cause bumps and cause a short circuit. While too few can result in weak soldering, so the amount of soldering wire must be appropriate. After the soldering iron tip is placed on the pins of the soldering component, put in the solder wire immediately. When the solder wire melts and reaches the expected range, immediately remove the solder wire and quickly remove the soldering iron head.

When soldering, the temperature should not be too low, otherwise the connect time between the soldering iron and the pins of the soldering component will be too short, so the temperature cannot reach or the heat is insufficient, the tin surface of the solder joint will not be bright, and the crystal will be rough, like tofu slag. It will cause weak soldering, which will make the soldering weak and form fake soldering. On the contrary, if the time is too long (generally no more than 5 seconds) and the temperature is too high, the solder wire will flow out, resulting in insufficient tin, which will cause instability, and may burn electronic components and printed circuit boards.

1)When soldering with a soldering iron, do not use too much force. It is not conducive to heat conduction, and will cause damage to the circuit board.

2)Before soldering, choose the size of the soldering iron tip that is suitable for the soldering material. If it is too large, it will cause damage around the circuit board, over-soldering of the solder joints, and excessive contact area.

3)When soldering, the solder wire should be placed in the right position. Hold the solder wire in the left hand and the soldering iron in the right hand. After the solder joints are fused, remove the electric soldering iron immediately.

4)Too high temperature and too long time will make the flux invalid and increase the thickness of the intermetallic compound.

5)After soldering, apply a layer of tin on the surface of the soldering iron head, which can not only maintain the soldering iron head but also facilitate the next use.

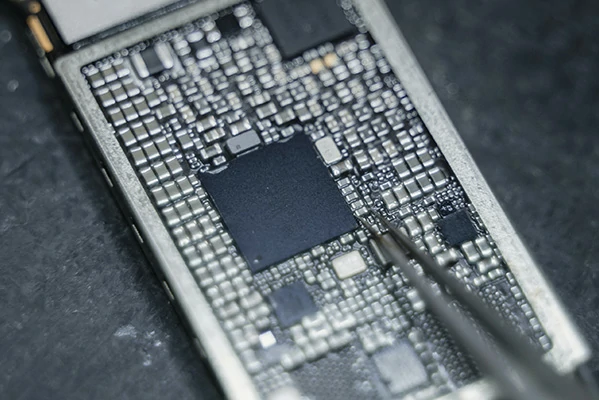

In the work of debugging and repairing electronic equipment, it is often necessary to replace some components. Of course, the premise of replacing components is to desolder the original components. Improper desoldering will damage the printed circuit board and the components that have been replaced. Desoldering is more difficult than soldering and requires the use of proper methods and tools. Improper desoldering can easily damage the components, or cause the copper foil to fall off and destroy the printed circuit board. Therefore, desoldering technology is also a basic operation skill that should be mastered.

General spot desoldering: Usually, the resistors, capacitors, triodes and other components on the integrated circuit board of electronic components are desoldered by heating and melting the solder joints with an electric soldering iron. You can first stand up the printed circuit board and clamp it with a clip. While heating the solder joints of the components with an electric soldering iron, gently clamp the pins of the components with tweezers to separate the components from the circuit board. It must be noted that when desoldering, wait until the solder joints are melted before dismantling, otherwise the components will be damaged or scrapped.

1)Multi-point desoldering:

When we desoldering multi-point components, the above method is not appropriate. When desoldering multi-pin integrated circuits or components, we generally use the following several methods.

2)Desoldering with a tin soldering iron or a tin remover

The soldering iron is very useful for the desoldering of electronic components. It can remove the replaced components without blocking the solder holes, and it is very suitable for various desoldering components. But it also has advantages and disadvantages. It needs to be desoldered one by one when desoldering, the efficiency is relatively slow, and the sucked solder must be removed in time.

3)Use a special electric desoldering tool

The dedicated electric desoldering tool melts the solder points on the pins of component after the tin suction nozzle is energized and heated. The electric desoldering tool has a built-in electric pump which can generate vacuum suction and can suck in the waste tin, so it is not easy to cause damage to the components around the components and the components of the circuit board.

4)Desoldering with hot air gun or infrared soldering gun.

Either a hot air gun or an infrared soldering gun can operate and heat multiple solder joints at the same time. After the solder joints are melted, the components are taken out. For the components on the surface of the printed circuit board, a hot air gun or an infrared soldering gun is the best choice.

The advantages of this method are that it is fast, simple and convenient, and it is not easy to damage the components and the copper foil on the printed circuit board.

1. After the desoldering is completed, remember to clean up the impurities on the circuit board and clean the circuit board to facilitate the next step of soldering.

2. If the leads of the solder joints are bent at a certain angle, the solder must be sucked off when desoldering, and then pry straight with tweezers before removing.

3. When desoldering, heating rapidly, highly concentrated, and action fastly.

4. When not in use, please put the handle on the stand to prevent accidents.

5. After the desoldering work is completed, pay attention to cooling the body, and put the soldering iron or soldering gun on the holder to wait for cooling before unplugging the power plug.

WhatsApp

WhatsApp