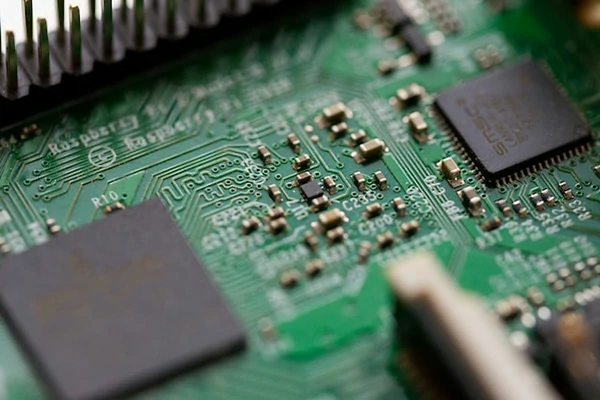

Soldering, the art of precision and connection, is a cornerstone of electronics. Yet, even the most experienced hands can stumble on common mistakes when using a soldering station. In this article, we'll guide you through the pitfalls to ensure flawless soldering results. With simple tips and tricks, we'll help you dodge these errors and create impeccable connections effortlessly.

1. Temperature Temptations

One common pitfall is improper temperature settings. Your soldering station's temperature must match the specific components and materials you're working with. Too much heat can damage components, while insufficient heat leads to weak connections. Ensure you're using the right temperature and always double-check before starting.

2. Rushing the Process

Soldering is an art that requires patience. Rushing the process can result in cold solder joints – unreliable connections that lead to performance issues. Take your time, allow the solder to melt properly, and ensure it flows smoothly to create a solid bond.

3. Neglecting Flux

Flux is your ally in soldering. It helps clean surfaces, improve solder flow, and minimize oxidation. Neglecting to apply flux or using it improperly can lead to weak joints and irregular connections. Remember to apply an appropriate amount of flux to achieve reliable results.

4. Poor Cleaning Habits

A clean work environment is vital for successful soldering. Dirty or corroded surfaces can hinder the solder's ability to bond effectively. Prior to soldering, make sure to clean both the components and the soldering iron tip. A clean start leads to clean connections.

5. Neglecting Safety Measures

Soldering involves high temperatures and potentially hazardous fumes. Neglecting safety measures like using proper ventilation, wearing safety glasses, and using heat-resistant materials can lead to accidents. Prioritize safety by following best practices and using protective gear.

6. Incorrect Soldering Iron Usage

Using the wrong type of soldering iron tip or applying excessive pressure can result in damage to both components and PCBs. Ensure you're using the appropriate tip size and shape for the job. Use a gentle touch and let the heat do the work.

Avoiding these common mistakes when using a soldering station is crucial to achieving high-quality solder joints and maintaining the integrity of your components. Remember to control the temperature properly, maintain your soldering iron, prepare the surfaces, employ correct soldering techniques, and prioritize safety.

AiXun Soldering Stations are the ideal choice for precise and reliable soldering. With advanced temperature control systems and digital displays, these stations allow for precise temperature adjustments and real-time monitoring. They boast rapid heating and temperature recovery, ensuring quick start-up and consistent heat output. Designed with comfort and safety in mind, AiXun soldering stations feature ergonomic designs, user-friendly interfaces, and safety features like automatic sleep mode and temperature lock. Whether you're a professional or a hobbyist, AiXun Soldering Stations provide the perfect solution for achieving exceptional solder joints.

Ready to elevate your business? For more information or get a quote, we look forward to partnering with you.

WhatsApp

WhatsApp